What to do if the saw cut is not square?

Maybe the work table is slightly tilted. Use an angle to check whether the worktable is at right angles to the band saw blade and correct the setting.

Too little tension on the band saw blade can also cause the saw cut to run. Then increase the band tension on the upper handwheel.

What to do if the saw blade jumps off the rollers despite correct settings?

If you have adjusted the inclination of the upper roller correctly, this should not happen. Check whether the rubber bandages of the track rollers are dirty or heavily worn. Clean dirty bandages or replace worn or damaged rubber bandages.

It often happens that the saw blade is pulled forward out of the guide when the workpiece is pulled back. If this cannot be avoided, always pull the workpiece back slowly and make sure that the saw blade remains in the guide.

What to do if the band saw makes unusual noises?

Regular noises, such as clattering or banging, can have several causes. On the one hand, it can be due to an imbalance. Sometimes chips and dust fall onto a track roller (usually the lower one) when changing the saw blade and remain between the spokes or on the inner rim. Check and clean the rollers.

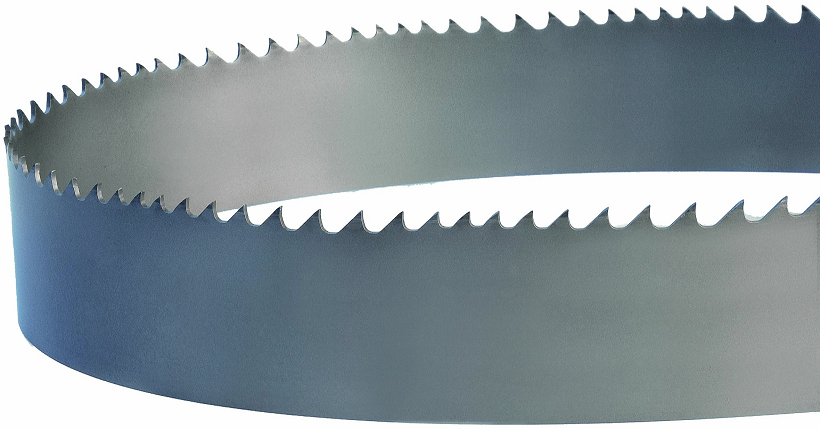

Beating noises at slightly longer intervals are usually caused by a damaged or kinked saw blade. Check the saw blade over its entire length and replace it if necessary.

What to do if the band saw does not start after changing the band saw blade?

Check whether the mains plug is plugged in. If this is the case, it is usually due to the safety contact switches that stop the band saw as soon as one of the doors is opened. Check that all doors are firmly closed and that the safety contact switches are working correctly.