I-Cold saw blade: Yintoni kunye neenzuzo

I-Cold saw blade: Yintoni kunye neenzuzo

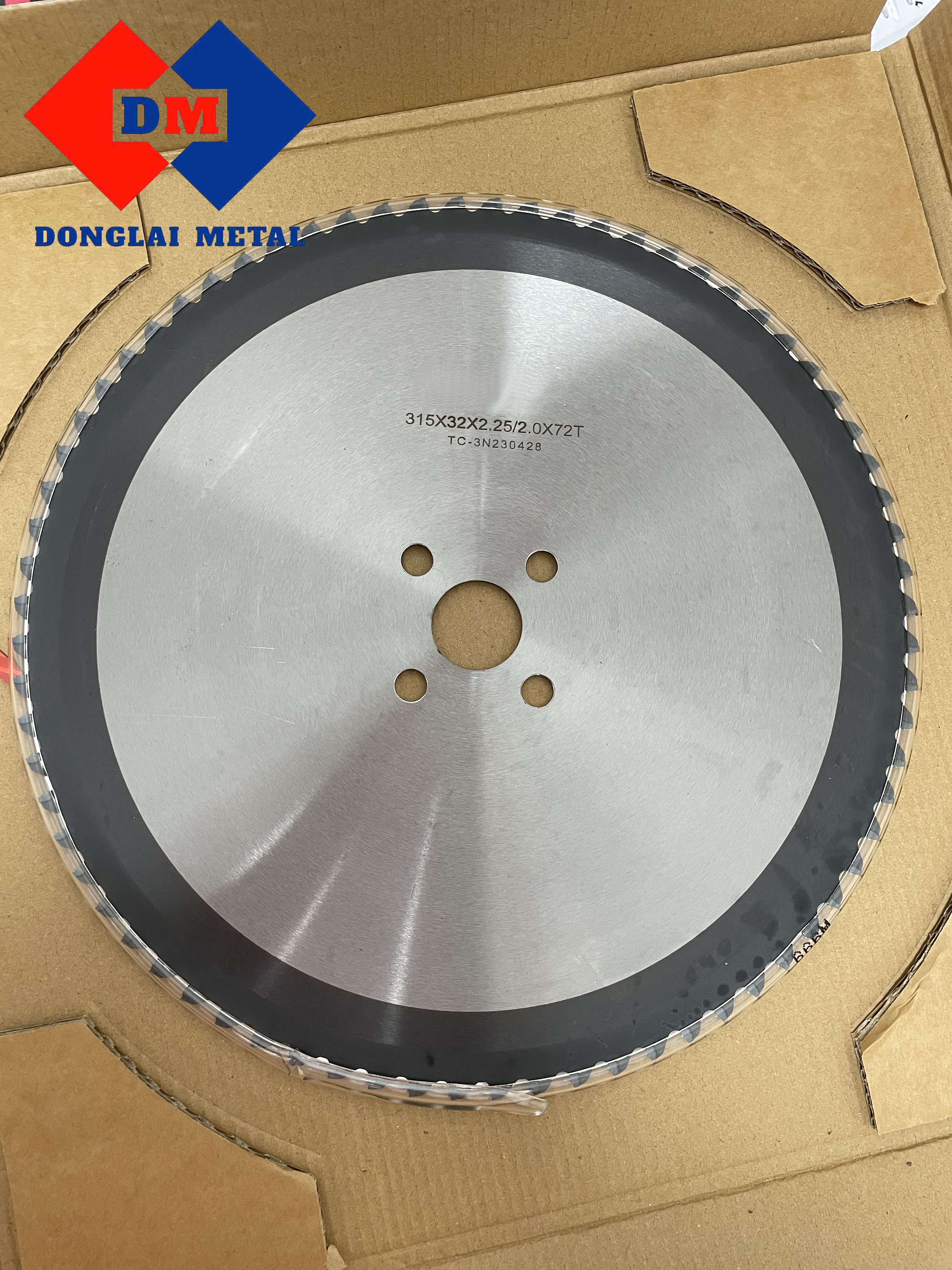

Isarha ebandayo, eyaziwa ngokuba yintsimbi yokusika ebandayo, ligama elisetyenziselwa ukuchaza inkqubo yokusika umatshini wesinyithi ojikelezayo. Ngethuba lenkqubo yokusika isinyithi, ubushushu obuveliswa ngamazinyo e-saw blade ukusika i-workpiece kudluliselwa kwi-sawdust, ukugcina i-workpiece kunye ne-saw blade ipholile. Yiyo loo nto ibizwa ngokuba yi-cold sawing.

Ukuthelekisa

(Xa kuthelekiswa neManganese Steel Flying Saw)

Ukusika i-Cold saw kunye ne-friction yahlukile, ngokukodwa kwindlela yokusika:

I-Manganese steel flying saha blade: Incakuba yesarha yentsimbi yemanganese ijikeleza ngesantya esiphezulu ukuze yenze ukukhuhlana kunye nomsebenzi. Ukungqubuzana phakathi kwe-saw blade kunye ne-workpiece ngexesha lenkqubo yokusika kudala ukushisa okuphezulu okubangela ukuba umbhobho odibeneyo odibeneyo uphuke. Le yinkqubo yokutshisa eneneni, nto leyo ekhokelela kumanqaku abonakalayo okutshisa okuphezulu kumphezulu.

Isarha epholileyo yentsimbi enesantya esiphezulu: ithembele ekujikelezweni okucothayo kwesarha yentsimbi enesantya esiphezulu ukuya kwimibhobho edityanisiweyo, enokufikelela kwiziphumo zokusika ezigudileyo nezingenaburr kungekho ngxolo.

Izinto eziluncedo:

Isantya sokusika sikhawuleza, sifezekisa ukusebenza kakuhle kokusika kunye nokusebenza okuphezulu.

Ukuphambuka kwe-blade kuphantsi, kwaye akukho burrs kwindawo enqunyiweyo yombhobho wensimbi, ngaloo ndlela kuphuculwe ukuchaneka kokusikwa komsebenzi, kunye nokwandisa ubomi benkonzo ye-blade.

Ukusebenzisa ukugaya okubandayo kunye nendlela yokusika, ukushisa okuncinci kakhulu kuveliswa ngexesha lenkqubo yokusika, ekhusela utshintsho kuxinzelelo lwangaphakathi.kunye nesakhiwo sezinto eziphathekayo zecandelo lokusika. Ngexesha elifanayo, i-blade yenza uxinzelelo oluncinci kumbhobho wensimbi kwaye ayibangeli i-deformation yodonga lombhobho kunye nomlomo.

Izixhobo zokusebenza ezicutshungulwe ngesantya esiphezulu sentsimbi esikiweyo zinomgangatho olungileyo wobuso:

·Ngokwamkela indlela yokusika ephuculweyo, ukuchaneka kwecandelo lokusika liphezulu, kwaye akukho burrs ngaphakathi nangaphandle.

·Umphezulu osikiweyo usicaba kwaye ugudileyo ngaphandle kokufuna ukucutshungulwa okulandelayo okunje nge-chamfering (ukunciphisa ubungakanani bokusebenza kweenkqubo ezilandelayo), ukonga zombini amanyathelo okucubungula kunye nemathiriyeli ekrwada.

·I-workpiece ayiyi kutshintsha izinto zayo ngenxa yokushisa okuphezulu okwenziwa yi-friction.

·Ukukhathala komsebenzisi kuphantsi, ngaloo ndlela kuphuculwe ukusebenza kakuhle kokusika.

·Azikho iintlantsi, uthuli okanye ingxolo ngexesha lenkqubo yokusika, okwenza kube nobungane bendalo kunye nokugcina amandla.

Ubomi benkonzo bude, kwaye i-blade inokuphinda iphindwe ngokuphindaphindiweyo usebenzisa umatshini wokugaya i-saw blade. Ubomi benkonzo ye-blade ebukhali iyafana neyodwa entsha. Oku kuphucula ukusebenza kakuhle kwemveliso kwaye kunciphisa iindleko.

Itekhnoloji yesicelo:

Khetha iiparamitha zokusarha ngokusekwe kwimathiriyeli kunye neenkcukacha zomsebenzi osikiweyo:

·Qinisekisa i-pitch yezinyo, ukumila kwezinyo, iiparamitha ze-angle zangaphambili nasemva zamazinyo e-sarha, ubukhulu bencakuba, kunye nobubanzi bencakuba.

·Qinisekisa isantya sokusarha.

·Qinisekisa izinga lokutya izinyo.

Ukudibanisa kwezi zinto kuya kubangela ukusebenza kakuhle kokubona kunye nobomi benkonzo ephezulu ye-blade.