- Super User

- 2025-05-09

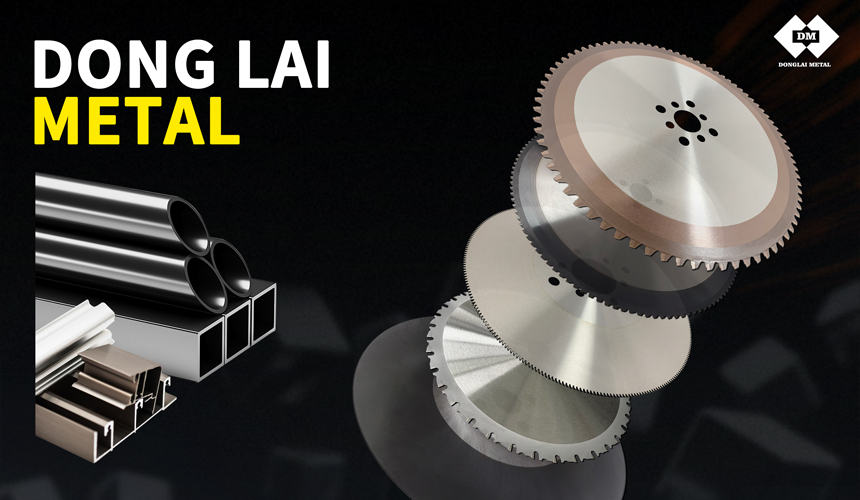

Ukusika kwensimbi kwabona kanjani ama-blade aqinisekisa ukunemba nokusebenza kah

Isihloko: Ukusika kwensimbi kwabona kanjani ama-blade aqinisekisa ukunemba nokusebenza kahle kokusebenza kwensimbi?

Ukusika kwensimbi kwabona amabala aqinisekisa ukunemba nokusebenza kahle kokusebenza kwensimbi ngezinto ezilandelayo:

Izinsizakusebenza ezisezingeni eliphakeme

Ubulukhuni obuphezulu futhi ugqoke ukumelana: inhloko ye-blade yokusika kwensimbi ebonile imvamisa yenziwa ngezinto eziphezulu ezifana ne-carbide ne-speed-speent carbide alloy njengesibonelo. Ihlanganiswe nge-carbide yensimbi ne-binder, futhi ubulukhuni bayo bungama-rocwell bungafinyelela ku-89-93hhra, okuphakeme kakhulu kunaleso sensimbi yensimbi.

Ubulukhuni obuhle: Ngaphezu kobulukhuni, i-saw saw blade impahla nayo idinga ukuba nobunzima obuthile bokuvimbela ubulukhuni ngenxa yenqubo yokusika.

Idizayini ye-WAWETONET

Ukwakheka kwe-sawtooth: Izimo ezahlukahlukene ze-sawtooth zilungele isimo esihlukile sokusika.Left kanye namazinyo afanele (ukushintshana amazinyo (ukushintshana amazinyo) yisimo esivame kakhulu. Ukuhlelwa kwamazinyo okushintshashintshayo kungakhiqiza amandla amakhulu okusika nokususwa kwe-chip ebushelelezi, okungavikela ngempumelelo i-chip blockage, kuthuthukise ukusebenza kahle kanye nekhwalithi, futhi kufanelekile ukunciphisa izinto eziningi zensimbi. Lapho usika amapayipi ensimbi amakhulu noma aminyene noma amaphrofayli, anganciphisa ukudlidliza, enze indawo yokusika ibushelelezi, futhi iqinisekise ukunemba kokunciphisa.

Ukukhethwa kwe-Tooth Pitch: usayizi we-tooth pitch kudinga ukufaniswa ngokufanele ngokwesikhulu nobulukhuni bezinto ezisetshenziswayo ze-cutting.forn ancishisiwe, ukunciphisa izintambo zensimbi, kunciphisa izinyo onqenqemeni kusuka ekulinyazwe ngenxa yokugcwala ngokweqile. Kuzuzisa futhi ngokususwa kwe-chip futhi kugcinwe nokusika okusebenzayo.

Inqubo yokukhiqiza ye-3.Precise

Ukulawulwa kokunemba okubucayi: Enqubweni yokukhiqiza yama-blades, ukulawulwa okuqinile kokunemba okuyisisekelo kubalulekile. Ukuphakama kwamazinyo ane-saw, ukunemba kwe-saw blade lapho uzungeza ukuqina kokusika, ukugwema ukunqunywa kokuqina futhi ngaleyo ndlela kuthuthukiswe ukucubungula ukunemba.

Ukusebenziseka kwekhwalithi ephezulu

Imishini ye-4.AddAddd and Technology

Imishini yokusika ukusebenza okuphezulu: ngokuhlanganiswa nemishini yokusika esezingeni eliphakeme efana nemishini yokusika i-CNC, ingathola ukulawulwa okunembile kwe-Iron Suppling, i-cutting systems ifakwe ngokunemba kokuphakelwa kwe-blades.

Ubuchwepheshe bokuqapha obunobuhlakani: Eminye imishini yokusika esezingeni eliphezulu nayo ifakwe uhlelo lokuhlola oluhlakaniphile olungakwazi ukuqapha amapharamitha ahlukahlukene kwinqubo yangempela, okufana nokushintsha i-accer yokusika isikhathi noma ukwenza izinguquko ezihambisanayo ukuze kuqinisekiswe ukuthi ikhwalithi yokusika nokusebenza kahle ayithinteki.

Ukusetshenziswa kwe-5.Corruct

Izilungiselelo zokusika ezinengqondo zepharamitha: Ngokusho kwezinto ezibonakalayo nobukhulu bensimbi bunqunywe, ngokufanelekile isivinini sokusika, ukunciphisa ijubane, ukuncipha kwensimbi kufanele kuncishiswe ngokufanelekile, futhi ukuncipha kwensimbi kufanele kuncishiswe ngokupholisa nokuthambisa ukunciphisa ukugqoka kanye nekhwalithi.

Ukulungiswa Nokunakekelwa Okujwayelekile: Ukuhlolwa njalo, ukuhlanza, ukugaya kanye nokubuyiselwa kwezindawo zokusika kwensimbi kubonakale futhi kuthinte ukusebenza kwayo okugciniwe futhi kuthinte amandla okusika njalo. Lapho ibala le-blade ligqoka ngezinga elithile, libuyise ngento entsha ngesikhathi ukuqinisekisa ukunemba nokusebenza kahle.